Greener ships, cleaner ocean

- Jody Paterson

What engineering solutions will it take to make ships more environmentally friendly?

Drop an electric motor into a ship and you’re all set to sail into a cleaner environment, right?

If only it were that simple, says a University of Victoria mechanical engineer whose research focuses on hybrid electric propulsion systems.

Zuomin Dong and his research team have studied and built advanced hybrid vehicles for a decade, winning dozens of awards. His team’s computer modelling tools take all operational factors into account to identify the “sweet spot” where vehicles achieve maximum fuel efficiency and emission reduction without sacrificing performance.

The team is now working on hybrid electric propulsion systems for ships, heavy-duty mining trucks and trains. BC Ferries is one of several industry partners working with Dong, all of them interested in fleet conversion but needing to know more about costs, logistics and impact on performance.

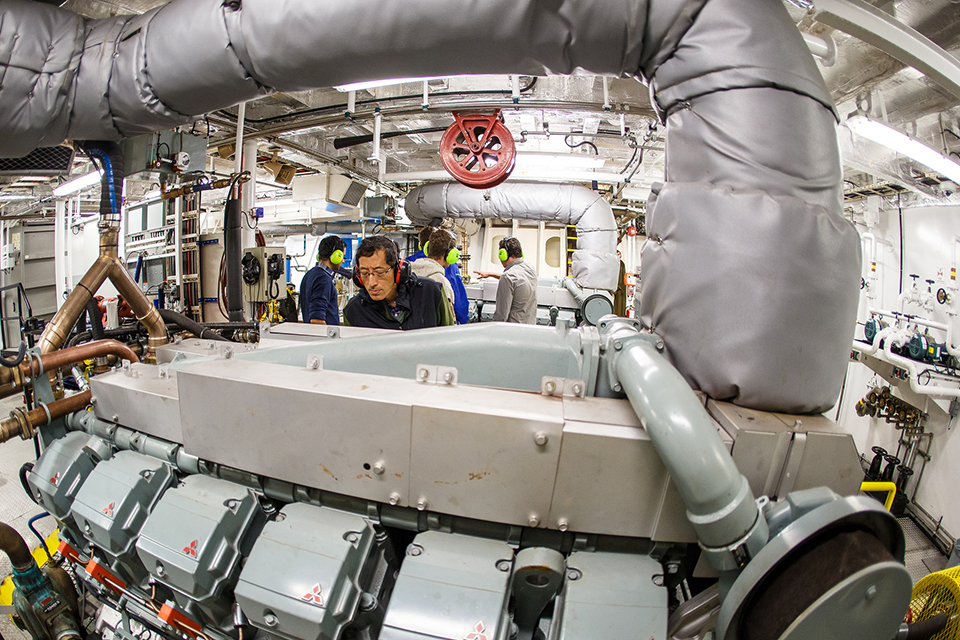

Ships are much more complex and challenging than cars, says Dong, who is also a member of UVic’s Institute for Integrated Energy Systems, a leader in sustainable energy systems research. While cars are mass-produced, mostly the same size and operate in similar conditions, every ship is unique and expensive, produced in small batches and operating on different routes with different cargo loads.

Cars face rain or snow, but marine vessels are up against waves, currents and heavy winds. They have different hulls, propellers and drags that perform differently depending on cargo and marine conditions, and whether the ship is travelling in open or protected waters. “You can’t design one system and use the same template for all others,” says Dong.

For BC Ferries, the challenge is to understand how much electrical energy a ferry will need to travel its route, and how that amount can be added back into the onboard batteries in the short time that a ferry is docked to pick up passengers, says Bruce Paterson, director of naval architecture for BC Ferry Services Inc.

Paterson says Dong’s team has been invaluable in helping the ferry service figure that out—using a computer design model that provides a unique profile of the ship as an integrated system.

Initially given the Brentwood Bay ferry as a testing ground, the team was an impressive 90 per cent right on predicted energy requirements the first time out, he adds.

Ship-induced noise has also been incorporated into the model to inform the design of propulsion systems and operating practices that cause cavitation. Caused by air bubbles from the propeller, cavitation produces a loud and persistent sound underwater that interferes with communication among many marine animals.

The combination of natural gas engines and hybrid electric propulsion shows considerable promise for “greener” ships, says Dong.

Natural gas is a cleaner fuel than diesel but doesn’t combust fully at certain loads. That characteristic limits reductions in greenhouse gas (GHG) emissions and dramatically increases discharge of hydrocarbons.

But in combination with a hybrid electric system, propulsion systems can be programmed to avoid these engine conditions and switch to electric power at high-risk times. “When we tested that using our model, we were able to reduce GHG by 19 per cent, and cut fuel costs by 39 per cent,” says Dong.

Major funders of the research include Transport Canada, Seaspan, and the Dennis and Phyllis Washington Foundation.

EdgeWise

Marine transportation currently accounts for 2.8 per cent of global greenhouse gas emissions—more than the total emissions produced by Canada in 2013. This number is projected to increase to five per cent by 2050.

The International Maritime Organization has set standards for vessel emissions. Regulations implemented by regional and national governments are forcing ship owners to meet these standards by seeking “green” solutions—such as hybridization and electrification of a vessel’s powertrain.

Dong’s hybrid electric propulsion system model is a collaborative, international effort. Colleague Peter Oshkai’s research team simulates fluid dynamics on a supercomputer; researchers from Italy’s University of Genoa verify the propeller-cavitation noise model; an East Coast team acquires operational data from different vessels; and researchers from Australia’s University of Tasmania help simplify propeller-thrust and noise models.

Many students involved in the project have become leading researchers and engineers on advanced hybrid electric propulsion technology, working at prominent companies including General Motors, Tesla, Ford, AVL Powertrain Engineering, and Seaspan.

UVic is a research leader on sustainable energy systems, climate modelling, climate change mitigation and adaptation, and the human dimensions of climate change. Our internationally recognized researchers are at the forefront of clean-growth technology, partnering with governments, industry and community groups to develop sustainable solutions and a low-carbon economy.

Photos

In this story

Keywords: clean energy, research, industry partnerships, climate, sustainability, engineering, Institute for Integrated Energy Systems, climate solutions

People: Zuomin Dong

Publication: knowlEDGE