Advancing the power grid

- Clare Walton

Next generation insulators for electrical transmission, distribution

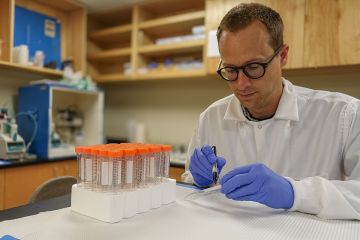

When University of Victoria chemist Dennis Hore looks to the sky he sees potential for a greener, more sustainable future.

That’s because Hore and his research team are investigating materials they hope will make up the next generation insulators for the electrical power grid.

Overhead transmission wires carry electricity in our communities, and insulators—the stacked disk-like objects—are an important part of the infrastructure. The life cycle of traditional ceramic insulators is coming to an end, says Hore, whose innovations in materials science are paving the way for a deeper understanding of the chemical and molecular make up of insulator materials and creating new ways to measure their performance using high voltage testing and modelling systems.

Ceramic insulators take in water and eventually crack, typically giving them a life expectancy of up to about 50 years says Hore. This makes finding a more resilient replacement crucially important. Hore is inspecting the material properties of new insulators that he hopes can withstand extreme weather and environmental stress, contributing to products that deliver stable, cost-effective power in rural and urban areas.

Hore’s research team can inspect insulator surfaces very closely—at a nanometre length scale or to a billionth of a metre. They are working with silicone, a promising alternative to ceramics because the polymer is not as impacted by changing weather conditions, especially rain. Silicone’s hydrophobic nature—or ability to repel liquid—causes droplets to form on the surface when wet, instead of absorbing into the core.

Silicone insulator testing

The team is researching how exposure to elements and chemicals, such as ocean spray and de-icing salts, affects an insulator’s ability to maintain its hydrophobicity over time. "Little research has been done to understand how silicone insulators exposed to chemical agents react when under electrical stress,” says Hore.

He is also researching how silicone insulators can withstand extreme summer and winter climates. Insulators face two unique challenges: chemical and biological resistance, says Hore.

Although testing has been conducted to understand these challenges, none has factored an electrical load, which is where Hore’s team comes in.

Using simulators developed by the research team to energize silicone to high voltage—40,000 volts is commonly used in power grids—Hore and his team are zeroing in on how polymer molecules react as the researchers cycle through wet and dry conditions. They also present insulators with de-icing agents and algae to test how the surface changes.

So far, they are noticing patterns that offer early clues about how the molecules behave under a range of conditions, which could one day impact how the insulators are manufactured and maintained.

While further testing is needed, Hore hopes that being able to provide industry with physical explanations for degradation in material performance will help create optimal insulators.

Our research has the potential to influence the choices made by the power utilities and industry, and help provide evidence for more environmentally friendly and efficient power generation. By working to understand molecular-level interactions, we are developing a stronger understanding of the material's properties and how it will weather over time.

— UVic chemist Dennis Hore

EdgeWise

Hydrophobicity is a key quality in materials science, or the study of new and existing materials for application across many disciplines. Materials can either be hydrophobic, repelling liquids like the droplets seen when rain hits a rain jacket, or hydrophilic having liquids stick to them or spread on their surface like the spreading of water as it slides across a glass window.

Since the early 1800s ceramic insulators have been the dominant material for electrical generation in the world. In 2014 it was estimated that 41 per cent of Canadian power grids that rely on ceramic insulators were reaching the end of life says Hore.

Replacing ceramic insulators with silicone-based options and other technologies would provide more environmentally friendly power generation by reducing greenhouse gas emissions, decreasing power outages and significantly lowering maintenance costs by reducing line maintenance and insulator replacement costs by half. This is in part because silicone insulators have a hydrophobic surface. Unlike ceramics, the surface of silicone insulators reacts to contact with liquids, repelling moisture and extending their life cycle.

Hore’s research is funded by the Natural Sciences and Engineering Research Council of Canada, in partnership with ASAsoft (Canada), which manufactures silicone insulators.

Photos

In this story

Keywords: research, Chemistry, clean energy, sustainability, environment

People: Dennis Hore

Publication: knowlEDGE