A UVic engineer is developing an easy way to detect mining's toxic leftovers

- Jody Paterson

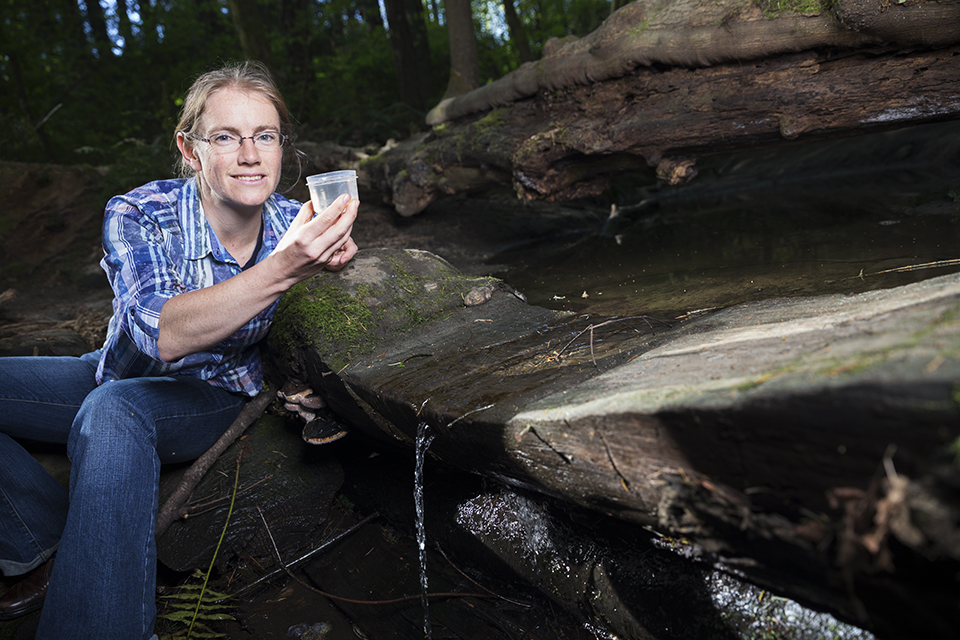

Even decades after a mine closes, people in surrounding communities can face serious health risks from drinking contaminated water. Communities in BC’s North are particularly at risk of arsenic poisoning due to the legacy of gold and uranium mines, says Heather Buckley, green chemist and professor of civil engineering at the University of Victoria.

Water is easily contaminated by arsenic and metals that leach out of rock and soil disturbed in the mining process. With no simple, quick or low-cost method for testing water, even short-term measures to address known problems typically end up delayed by weeks or even months until lab results are available.

Buckley is working on a solution. Her research aims to develop a low-cost test strip—along the lines of those used for glucose monitoring— that immediately identifies health-threatening levels of the most common contaminants from mining.

With a goal of creating a simple test strip that sells for a dollar or two, Buckley’s work not only envisages giving communities the power to test their water supply at any time and get immediate results, but to have direct access to the data they need to advocate for change or intervention. “When you dig up rocks for mining the metal extracted accounts for maybe one per cent of that material,” explains Buckley, whose research is funded by the Canada Foundation for Innovation. “Then those big piles of rock are out where the dust can blow. Along comes the snow melt, the spring washout, and whatever was in and on those rocks goes straight into the river.”

Arsenic occurs naturally in the ground. Rock-crushing spreads it around as a fine dust across the landscape. Mercury, chromium, cadmium and lead are all well-recognized health hazards from mining processes that also affect drinking water. Health effects from such toxins can take years to manifest, at which point the damage has been done.

Buckley’s high-tech test strip builds on existing research around molecules specifically designed to capture metals. Such molecules will be used to create a “stickiness” on the test strip for the most problematic metals. She anticipates having a prototype ready for testing within five years, and stresses that keeping them affordable is a critical component of the work.

“I want to make technology that can be viably used in rural Bangladesh,” says the “green” engineer and chemist, named a Green Talents Fellow in 2015 by the Fraunhofer Institute for Solar Energy in Freiburg, Germany.

Buckley is hopeful her research will eventually change mining practices. While her current focus is to empower communities to monitor the water supply, she notes that the work also gives companies the tools to show they can do better.

“It creates a space where communities and industries can rebuild trust. It takes away some of the divisiveness,” says Buckley. That’s an important goal this year, which is the launch of the UN International Decade for Action: Water for Sustainable Development.

A secondary aspect of Buckley’s research is to apply the same “stickiness” technology used for the test strips to create a method of extracting valuable metals from mine tailings and boost the amount of ore that mining companies are extracting.

In time, the research could ultimately result in a reduction in mining due to higher returns, and lead to new extraction techniques that don’t require the use of additional toxicants like mercury in the extraction process.

Photos

In this story

Keywords: research, water, sustainability, engineering, civil engineering, mining, health

People: Heather Buckley

Publication: The Ring